Semi-Automatic Pet Stretch Blow Molding Machine FS-1000HD2

Categories : Automatic Blow Molding Machines

One Heating Machine One Stretching Machine. Small size and unoccupied space. It could produce 300c.c.~20Liter PET bottles and suitable for various bottles. Semi-auto PET Stretch Blow Molding Machine is suitable for limited production but various products. This type of machine can produce plastic containers for the widest range of product's capacity. Moreover, machine's size is small and occupies few space.

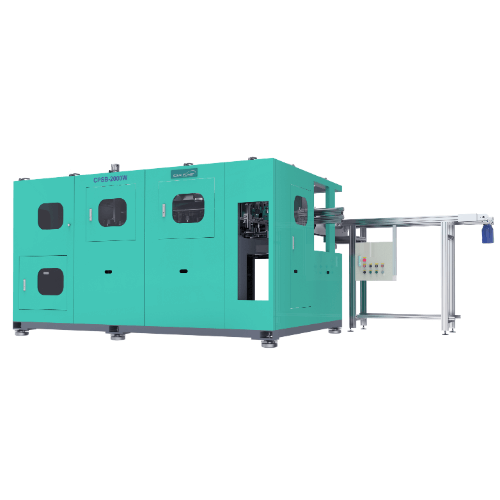

PET Automatic Stretch Blow Molding Machine for Hot Filling Bottles

Categories : Horizontal Blow Molding Machines

The CMA (H) series stretch blow molding machines produce hot filling bottles for products such as fruit juices, isotonic drinks and RTD tea. These machines have a unique design according to the effect on the PET material. Multiple blowing steps reduce PET residual stress. Hot filling PET bottles are available for high temperatures ranging from 82°C to 95°C without deformation. This is an incredible success in the hot filling beverage domain.

PET Fully Electric Stretch Blow Molding Machine

Categories : Electric Blow Molding Machines

A handle bottle makes it easier to carry and pour from a container to container. CMS series stretch blow molding machine equipped with a robot device is the choice of making bottle with handle. The container with a firmly fixed rigid polypropylene handle ensures the shape that does not been distorted, and it is currently used for new products, especially for family size packs.

Large Volume PET Blow Molding Machine-W/L Series

Categories : Automatic Blow Molding Machines

Large Volume PET Blow Molding Machine-W/L Series Robust hydraulic clamping.Double robotic arms for speedy preform loading.Cost Effective machine that is also easy to maintain.Compact structure for small floor foot print.Modular design for easy maintenance.

PET Stretch Blow Molding Machine for up to 1500ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

PET Fully Electric Stretch Blow Molding Machine Series for Cosmetics Bottles

Categories : Electric Blow Molding Machines

PET Fully Electric Stretch Blow Molding Machine Series for Cosmetics Bottles

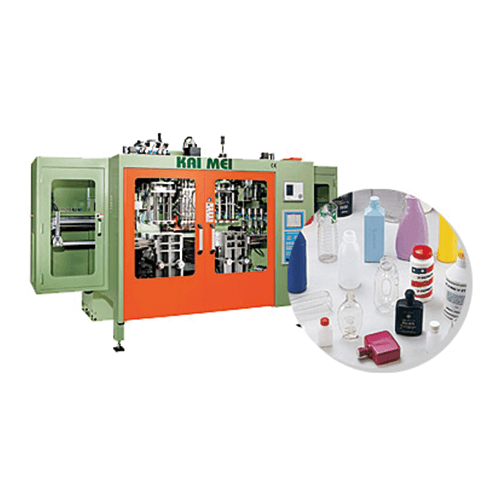

Blow Molding Machine PBSS SERIES 605 / 705 (S / D / T / Q)

Categories : Injection Blow Molding Machines

Double Stations Series Double station machine, full automatically, suitable for producing high-production runs of medium size bottles, ex. Cosmetic bottles detergents, etc. Mold-platen moves properly with high stability and high efficiency Three tie-bar horizontal traveling mold carriage combined with German linear motion guides for outstanding performance and high efficiency. This series is designed to meet high production and small size container requirements. Available to equip with auto de-flashing device and take out robot to achieve fully automatic and highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, convenient and user-friendly operation.

Blow Molding Machine Multi Layer Series

Categories : Electric Blow Molding Machines

VS series: suitable for visistripe bottles (ex. Motor oil bottle) -TC series: for the production of two-color plastic containers or toys -TL series: suitable for 2-layer bottles (ex. Cosmetic bottle only outside layer with pearl or color & made of virgin material) -Double-head or 3-layer machine can be delivered to order

Fully Electric Co-Extrusion Blow Molding Machine (Dual Diehead & Double Station / Visi Strip)

Categories : Automatic Blow Molding Machines

Chia Ming has developed Fully Electric Blow Molding Machine for the packaging industry producing pharmaceutical, cosmetic and beverage bottles in clean-room. Fully Electric Blow Molding Machine is a total new innovative design with servo motors controls which significantly reduce energy consumption, give higher production rate, noise level much reduced, in long term total production cost being dramatically reduced.

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Horizontal Blow Molding Machines

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.

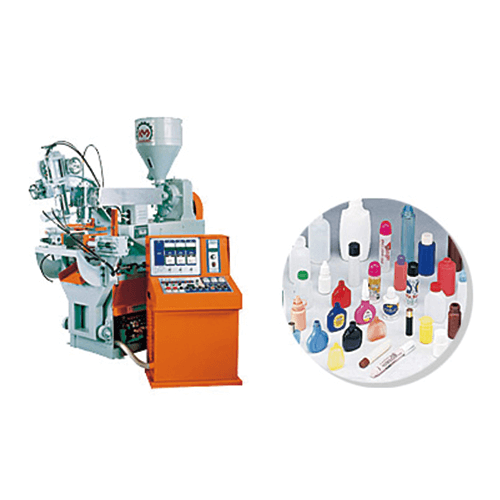

Small Blow Molding Machine

Categories : Electric Blow Molding Machines

Small-Continuous Type Blow Molding Machine This series model can produce small size containers ranging from 20mL to 10L for applications such as cosmetics, beverages, edible oil, pharmaceutical use, chemicals, housewares, and other industrial purposes. With the energy-saving system option, this machine can save up to 20% of power consumption. Some of the most common applications for small blow molding machines are: Lubricant oil bottles Laundry detergent bottles Cosmetic bottles Pesticide bottles Pharmaceutical bottles Multi-color kettles PVC cans Moreover, small blow molding machines can be customized according to the client’s needs of production: It can be a single or double station machine A visible stripe extruder unit can be added to observe liquid level It can include an auto-deflashing unit and many other features to make the machine as automatized as possible. An automatic extrusion blow molding machine is many times preferred because it leads to the reduction of manpower need which results in reduced costs, increased efficiency, and time savings for an organization.

PET Stretch Blow Molding Machine for Wide Mouth / Large Containers

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET large volume bottles, oval bottles, flat bottles and jars with volumes up to approximately 6000ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Suitable for clean lotion, edible oil, detergent, pickle food, etc. Small & Medium Volume Bottles

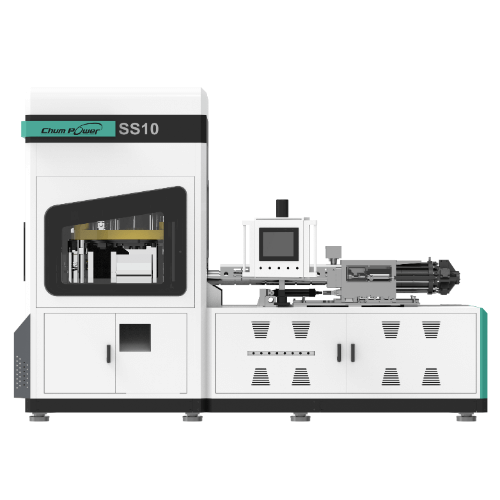

One Stage Injection Stretch Blow Molding Machine - SS10

Categories : Injection Blow Molding Machines

One-stop production machine. Specially designed and developed for small volume diversified production and special bottle designs. Finished products with glossy, complete, and untarnished appearances. Suitable for high-priced and high-quality bottle production. Fulfilling all bottle requirements with just one machine. The removal of two-stage heating can save up to 40% of electricity.

PP Stretch Blow Molding Machine

Categories : Automatic Blow Molding Machines

This PP bottle blow machine is dedicated to the production of pharmaceutical packaging and high temperature hot filling heat resistant bottles. Today the chemical resistance and suitability for steam sterilization of PP proves a winning combination. At CHIA MING Machinery, our second generation of PP stretch blow molding machine is available. The specialized design of these machines takes advantage of the characteristics of PP to ensure the highest quality.

Continuous Extrusion Blow Molding Machine with Visi-Strip function

Categories : Electric Blow Molding Machines

This series is excellent for producing containers such as engine oil bottles, machine oil bottles, gasoline bottles, and similar containers. A small screw can be specially installed to indicate the color of the bottle leveling line.

Semi-Automatic Stretch Blow Molding Machine

Categories : Automatic Blow Molding Machines

Application:Wide-neck jar, large volume bottle, vase, Oval, Off center, Petaloid, Square, Flat, Round bottles yicheen Suitable for High-priced and irregular shape bottle’ vase LCD screen computer system, 48 sets memory function for mold date. Circular cutter feed/withdraw and angle in position by servo automatic. One spindle approved set up 16 modes cutting in the meantime. Spindle and cutter rotate set up by touch panel and interchangeable rotary direction. The wide neck sealing motion employs hydraulically operated direct pressure drive. Preform heater outlet can be adjusted in vertical and horizontal direction to suit all types and sizes of bottle. Convenient mold open and mold change.

PET Stretch Blow Molding Machine for up to 600ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

PET Automatic Stretch Blow Molding Machine for Small Mouth Jar/Container

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET large volume bottles, oval bottles, flat bottles and jars with volumes up to approximately 6000ml. Ideally suitable for applications where stringent quality requirements have to be met. Suitable for clean lotion, edible oil, detergent, pickle food, etc.

PET Semi-Auto Stretch Blow Molding Machine

Categories : Automatic Blow Molding Machines

This semi-auto stretch blow molding machine is the most cost effective solution for low level production of bottles, containers, and jars in small to large sizes.

Blow Molding Machine PBA Series

Categories : Horizontal Blow Molding Machines

These machines are high cycle pneumatic blow-molding machines, suitable for popsicles & wide variety small size bottles.

5 Gallon Bottles PET Fully Electric Stretch Blow Molding Machine

Categories : Automatic Blow Molding Machines

CMSQ1 PET all electric stretch blow molding machines are suited for 3 gallon to 5 gallon water bottles.

PET Sretch Blow Molding Machine - Small Capacity of Diversity Bottle Production Line (LM Series)

Categories : Automatic Blow Molding Machines

Automatic PET stretch blow molding machine LM series match with high-speed precision blowing valve, air recovery converting to pressure operation will reduce air consumption. Preform from hopper transfer to unscrambler, automatically deliver to single channel by sequence. Shorten heating pitch to decrease energy waste and increase heating efficiency. Automatic PET stretch blow molding machine LM series adopt continuously centralized heating method Cooling ramp and air blowing device, effectively isolating preform neck to avoid preform neck deformed causing by overheating.

PET Stretch Blow Molding Machine - TEM12S2

Categories : Automatic Blow Molding Machines

Blower power consumption for 1000 bottles: 2Wh Air Compressor power consumption for 1000 bottles: 6 kWh compact space Screw driven controlled by servo motor providing fast and smooth motion Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating Low-pressure air compressor will NOT be required due to high-pressure recovery system. High efficient air recovery system up to 45%

PET Stretch Blow Molding Machine - EX02MC

Categories : Automatic Blow Molding Machines

● Blower power consumption for 1000 bottles: 2Wh. ● Air Compressor power consumption for 1000 bottles: 6 kWh compact space. ● Screw driven controlled by servo motor providing fast and smooth motion. ● Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating. ● Low-pressure air compressor will NOT be required due to high-pressure recovery system. ● High efficient air recovery system up to 45%.

PET Stretch Blow Molding Machine - The World's Most Energy Efficient Bottle Production Line (EM Standard Series)

Categories : Automatic Blow Molding Machines

Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

Full Electric Blow Moulding Machine

Categories : Electric Blow Molding Machines

Full Electric Blow Molding Machine for 200ml - 500ml shampoo bottle

Cosmetic Bottle / Detergent Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging

PET Stretch Blow Molding Machine - Economy Affordable New Choice (EX Series)

Categories : Automatic Blow Molding Machines

● Blower power consumption for 1000 bottles: 2Wh. ● Air Compressor power consumption for 1000 bottles: 6 kWh compact space. ● Screw driven controlled by servo motor providing fast and smooth motion. ● Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating. ● Low-pressure air compressor will NOT be required due to high-pressure recovery system. ● High efficient air recovery system up to 45%.

Carbonated Soft Drink Bottle

Categories : Horizontal Blow Molding Machines

Servo motor power and pneumatic combination structure. Stable, environmentally friendly, energy-efficient, low noise, low pollution. Blow Molding machine Breakthrough traditional heating methods and low energy consumption. We included gas recovery device to reduce air consumption of air compressor gas. Modular structure design, simple, reasonable and easy to operate and maintain PET Stretch Blow Molding Machines. Reasonable space configuration, small footprint. Easy-to-understand human-machine interface of machines and operation is easier. All components use internationally renowned brands to ensure accurate and stable operation.

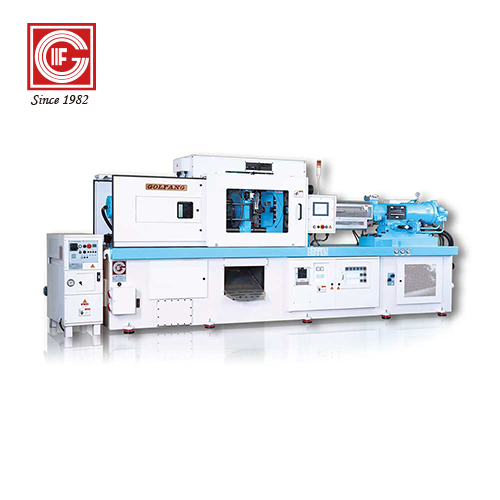

Single-Stage Injection Blow Molding Machine - IB Series

Categories : Injection Blow Molding Machines

Advanced Single Stage Blow Molding Machine Commonly used in the production of pet bottle, the mechanical design of Golfang Single Stage Blow Molding Machine is based on the blueprint of the world's most popular machine- the plastic injection machine with pressure booster ram system. Solid construction, durability, high precision, high stability, easy operation, easy maintenance and low running cost.

PET Stretch Blow Molding Machine -TEM16S2

Categories : Automatic Blow Molding Machines

Blower power consumption for 1000 bottles: 2Wh Air Compressor power consumption for 1000 bottles: 6 kWh compact space Screw driven controlled by servo motor providing fast and smooth motion Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating Low-pressure air compressor will NOT be required due to high-pressure recovery system. High efficient air recovery system up to 45%

PET Blow Molding Machine - Wide Mouth Bottle

Categories : Horizontal Blow Molding Machines

Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

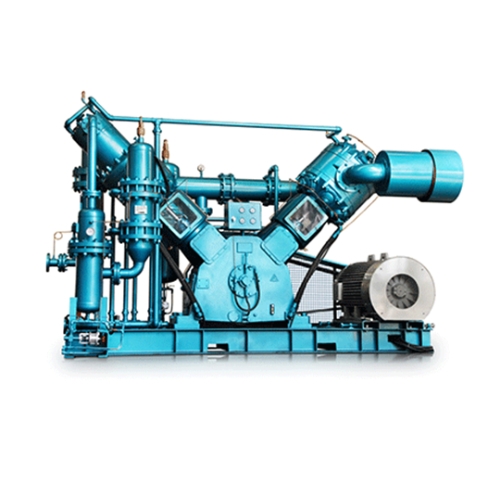

Air Compressor

Categories : Air Compressors

Oil-free High Pressure Reciprocating Compressor features for PET Bottle Blowing Machine: High efficiency models Greater compression efficiency More air generated Less power bills Special cooling and moisture design